Traditional Oak Frame Buildings

Craftsmanship, sustainability & customer service.

Call 07954 181 196

Understanding oak frames.pdf

Types of oak frames.pdf

Glazing green oak frames

There are three methods of glazing green oak frames :-- Directly - this involves seating the units either within the envelope of the frame, or on the external face of the frame.

- Secondary - which involves securing the units in a separate frame on the external face of the frame.

- Casement - where units are within a separate window frame, like normal windows.

Direct glazing

Glazing can be either directly onto the external face, or within the oak frame. These methods often work out to be the cheaper options, but some methods can be more effective than others, especially on a 'green' oak frame. The main consideration with all these methods needs to be requirements for opening windows. There are four methods possible to direct glaze :-Quadrant glazing

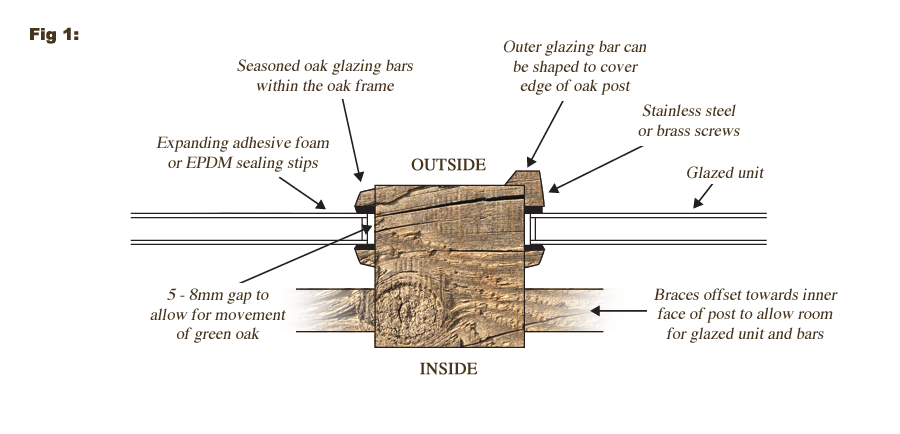

Glass units are seated with the posts of each section of the frame (fig 1), held in place with quadrant beading, made from air dried oak. EPDM tape creates the weather seal. This method requires special consideration given to the movement and shrinkage of the oak frame. If this is not duly considered, then failure of the glazing with occur, resulting in rain ingress, and remedial work to correct.

If this is not duly considered, then failure of the glazing with occur, resulting in rain ingress, and remedial work to correct. Elevations prone to weather extremes can benefit from improved sealing, by using a 'wrap around' quadrant.

This method generally proves to be the quickest, and least expensive, but runs the highest risk of failure.

This method generally proves to be the quickest, and least expensive, but runs the highest risk of failure.

Rebate glazing

The glass is seated in a rebate, which is cut into the arris on the exterior face of the frame, in each frame section. The units are then held in situ with quadrant beading, and sealed with EPDM tape, as in fig 1.

Inside, the visual effect is less imposing, as the glass blends into the frame. This method requires a greater detail of planning during the frame machining process, to allow for the rebating. Hence this will be more costly.

Rebate facia glazing

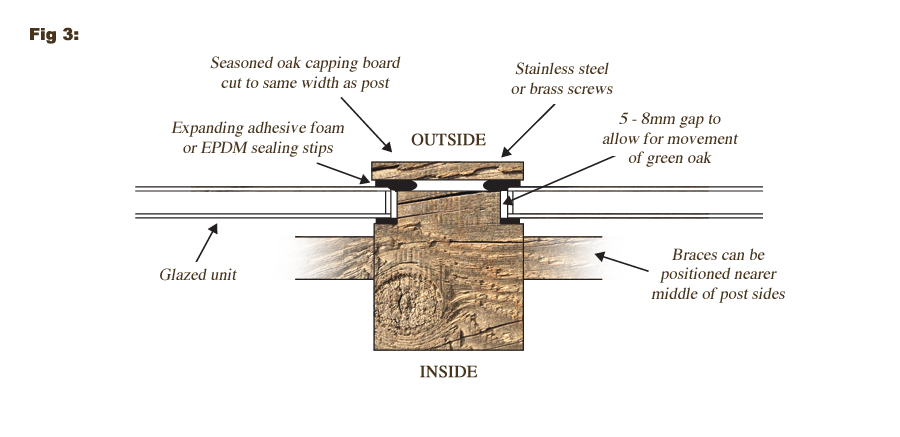

Here, the rebate cut into the exterior frame arris is shallower, allowing a fuller post depth view internally. The unit is held in position with an exterior elevation air dried fascia board, and is sealed as previous, with EPDM tape.

A greater seal against the elements, and allowance for shrinkage in the frame, is achieved by this method. From the outside, the appearance is off a full oak frame, as the fascia's are the width of each post.

Direct facia glazing

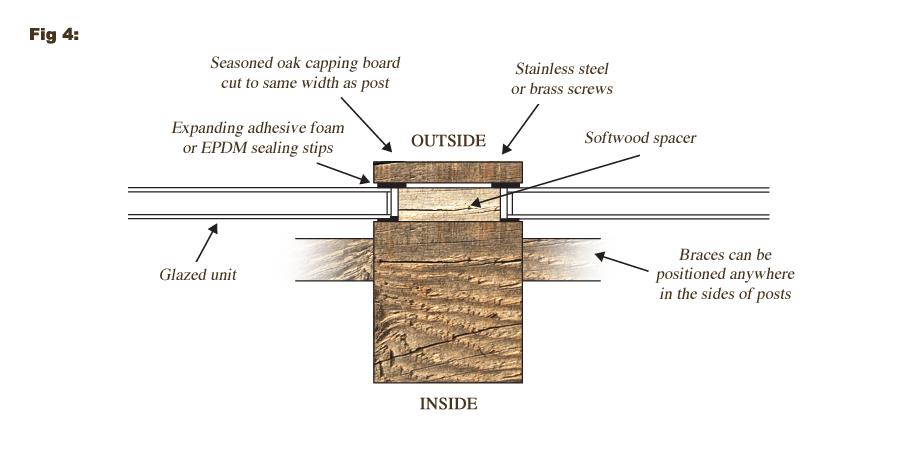

This method sees the glazing units seated on the exterior elevation of the frame, and as with rebate fascia glazing, secured in place with an air dried fascia. This method requires softwood spacer battens to be fixed to the exterior face of the frame, the same depth as the glazing unit and EPDM tape combined. The glazing unit is seated on a similar depth batten, which is either softwood, or air dried oak, dependant on the method used on the bottom edge of the glass. This is explored further on.

The glazing unit is seated on a similar depth batten, which is either softwood, or air dried oak, dependant on the method used on the bottom edge of the glass. This is explored further on.

This method allows a greater seal against the weather, and the greater tolerance for movement and shrinkage in the green oak frame. This is because the glass unit is in effect 'floating' on the exterior face. It gives a 'full' oak frame perception from inside and out.

This method allows a greater seal against the weather, and the greater tolerance for movement and shrinkage in the green oak frame. This is because the glass unit is in effect 'floating' on the exterior face. It gives a 'full' oak frame perception from inside and out.

* Other elements for consideration:

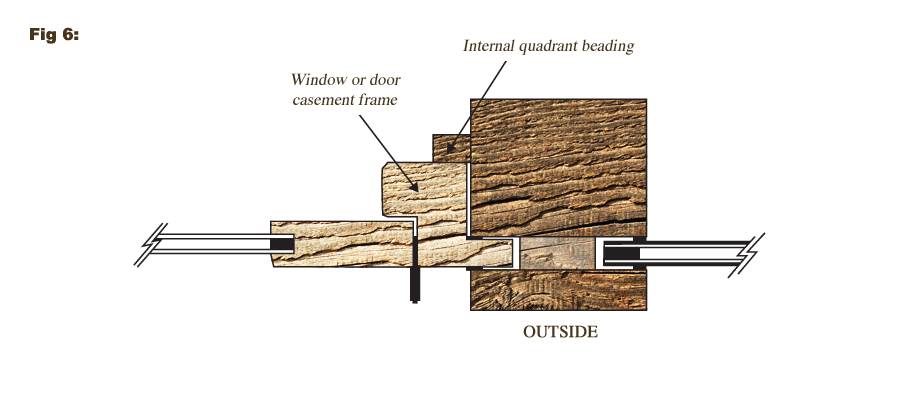

If fascia glazing is over two storeys, or even in a pitched gable end single storey, then special consideration has to be given to the mid wall beam. In particular, the fascia board needs to be split, and a form of flashing (generally lead or copper) needs to run between the two (fig 5). * Doors and casement windows can be more easily factored into the design with this method of glazing, as in fig 6.

* Doors and casement windows can be more easily factored into the design with this method of glazing, as in fig 6.

If fascia glazing is over two storeys, or even in a pitched gable end single storey, then special consideration has to be given to the mid wall beam. In particular, the fascia board needs to be split, and a form of flashing (generally lead or copper) needs to run between the two (fig 5).

* Doors and casement windows can be more easily factored into the design with this method of glazing, as in fig 6.

* Doors and casement windows can be more easily factored into the design with this method of glazing, as in fig 6.

Finally, the exterior view of the glazing finish on the bottom edge can be design in several different ways. Fascia borders can be attached to pre fixed battens, which the unit is seated on. This gives the complete oak frame look (fig 7). The glazed unit can be 'stepped' on the outward facing piece of glass, which in turn creates the necessary water drip for rain runoff.

This 'step' can then either be left clear, with the lead or copper flashing visible from behind (fig 8), or a colour film (usually black) can be adhered to the step, which then hides the flashing behind (fig 9). If left clear, then the 'seating' batten becomes a piece of air dried oak (fig 8a), screwed and plugged in place, whereas if filmed, then the batten would be softwood, as with the rest of the frame.

To summarise, each method has its advantages and disadvantages. Those being:

- The level of protection given from the weather, the later ones being the best.

- The amount of carpentry required to achieve, rebating being the most.

- The cost of the overall frame and glazing element of the build, secondary frames being the most.

Casement windows and doors

This final method is as simple as it sounds. Separate 'casement' windows and doors, as you would find in any home, can be manufactured, and installed within the frame. There is no rebating or fascia boards, but a larger section quadrant beading is used, and pinned to ONE face only (usually the oak frame). This allows for the shrinkage in the frame, as the quadrant moves with the frame. Compriband foam tape is used around the edges of the casement frames, which continues to expand as the frame shrinks, giving a full weather tight seal.

This method is expensive, especially if the doors and windows are manufactured from kiln dried oak, and can be the most ineffective method (if done wrong), to combat the frame shrinkage and warping.

Extreme pressures from the frame movement can be exerted on the windows and doors, and in turn damage the actual casement frames. The process of installation requires the casements to be 'floating' inside the oak frame, and all gaps are sealed with compriband expanding foam tape. These gaps are then covered with quadrant beading, both internally, and externally.

This method is expensive, especially if the doors and windows are manufactured from kiln dried oak, and can be the most ineffective method (if done wrong), to combat the frame shrinkage and warping.

Extreme pressures from the frame movement can be exerted on the windows and doors, and in turn damage the actual casement frames. The process of installation requires the casements to be 'floating' inside the oak frame, and all gaps are sealed with compriband expanding foam tape. These gaps are then covered with quadrant beading, both internally, and externally.

This method also allows for windows and doors to be a material other than wood, such as:

One final point to note is, with ALL these methods described, if undertaken by a competent person, with knowledge of the required processes, you can achieve a weather tight seal, and there should NEVER be the need to use silicone sealants. No matter if it is low modulus, or hard setting, IT IS NOT NEEDED!

- pvcU

- Aluminium

- Alu-timber (ppc)

One final point to note is, with ALL these methods described, if undertaken by a competent person, with knowledge of the required processes, you can achieve a weather tight seal, and there should NEVER be the need to use silicone sealants. No matter if it is low modulus, or hard setting, IT IS NOT NEEDED!